Hi-Fi Technology of CD-R Burning

Companies and firms that produce some products tend to hide the most important thing: the production technology. But how lucky we are: some information has trickled back from PolyDan, and now I put it out below.

But firstly there is a short excursus to the history of CD.

In 1980 Sony and Philips released a book of standards for the format of CD — Red Book.

In 1980 Sony and Philips released a book of standards for the format of CD — Red Book.

Orange Book, the format of CD-R and CD-RW (CDWO) was released in 1988.

There were specified the main storage formats: PCM 44,1 kHz, 16 bit, bitreiter 1411,2 Kbit/s. But as for the recording time standard there was an interesting story: Phillips offered to make discs for one hour of recording time and with a diameter of 10.5 cm, while Sony insisted on 74 minutes of recording time and a disc diameter of 12 cm explaining its proposal that the 9th Symphony of Beethoven has the same duration, namely 74 minutes. Thus, Beethoven helped adopt the modern diameter of CD!

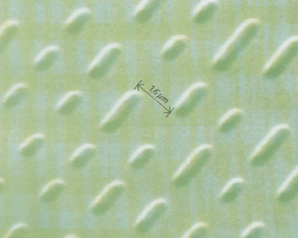

Let’s continue. The maximum recording time (modern one) is 79.4 minutes. The minimum recording time is 4 sec. Reading speed is 1.2 — 1.4 m/sec. Track spacing is 1.6 microns, pit width is 0.4 micrometers and its depth is 0.12 m.

In 1982 the German plant in Langenhagen was the first who released the CDs: Richard Strauss “Alpine Symphony” and ABBA “The Visitors”.

In 1982 the German plant in Langenhagen was the first who released the CDs: Richard Strauss “Alpine Symphony” and ABBA “The Visitors”.

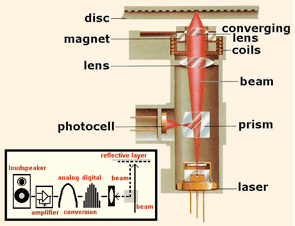

The above-stated technical information says that the optical mechanical recording of the new format required both mechanical and electrical precision when recording, duplicating and reproducing.

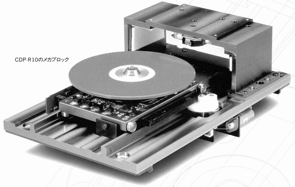

And if the master tape recording and factory production process chains remained virtually unchanged, the equipment reading information from a disk improved by leaps and bounds. Mechanics of disc rotation was advancing from electromotor drives, from children’s toys with thin 2-millimeter shafts to belt drives with vibro-decoupling based on helium shock absorbers. And as for the optical head mobility system, it progressed from the radius to fastened one (it was a disc who moved).

And if the master tape recording and factory production process chains remained virtually unchanged, the equipment reading information from a disk improved by leaps and bounds. Mechanics of disc rotation was advancing from electromotor drives, from children’s toys with thin 2-millimeter shafts to belt drives with vibro-decoupling based on helium shock absorbers. And as for the optical head mobility system, it progressed from the radius to fastened one (it was a disc who moved).

And the reason is that the discs produced in great quantities were curve, of different thickness and with irregular edges (this is the technology of liquid (helium-like) polycarbonate pouring in glass matrix). Discs «shook» drive shafts which, in its turn, shook an optical reading system, which because of the shaking did not have time to take an accurate information.

Pits being poured with gel were with smooth oncoming and outgoing edges, which gave additional reflections (signals). Digital matrix which were read incorrectly due to additional reflections and vibrations were sent then for correction in the so-called protocol C2 dealing with the approximation of lost or extra-acquired information. The approximation algorithm was a priority for manufacturers, and now we can only guess how good it was.

One more notorious drawback of the system, a clock signals jitter, will be discuss in the next article.

In CD-R a method for pits obtaining consisted in a change of coating reflective capabilities. The pits edges were clearer and the reflections which they produced had no additional «tails». That is the sound of copies produced with a good player was better than the original! This is the paradox but it is the core of the issue.

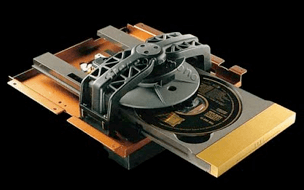

To fix warped discs, a system with an additional disk having the conic CD contact area was invented. Degree of taper was small, about 3 degrees, but it was enough to get a smooth reading surface.

But the non-uniform thickness of pouring and the subsequent reading ray defocusing failed to win.

Now you are ready to read about the recording technology from PolyDan.

Now you are ready to read about the recording technology from PolyDan.

The work begins with selection of original phonograms according to the criteria of recording quality/music content. Only the branded discs can be accepted for this kind of work. Using this approach of the phonograms selection, in order to burn one PolyDan disc, one needs to listen to several HUNDRED branded discs.

Next the disc is demagnetized using the equipment FURUTECH. The effect of such the procedure is completely stunning. Many people do not believe that their discs have so good sound after this treatment.

The disk prepared in such a manner is installed in the reading system with mechanisms of CDM 9 pro, VRDS, S.P.M. Why there are so many of them? Because each of them has its own sound, and the specific reading mechanism is selected for the particular phonogram.

This approach applies to the whole further processing chain of recording.

In addition, all mechanical devices go through its moving parts cleaning and washing from old grease and dust, and then they are re-lubricated with Swiss watch oil SYNT-A-LUBE. If you do this kind of work, the result, namely increase of sound quality, is ensured.

Then a signal arrives at input of an analog tape recorder with a corrector on lamps TELEFUNKEN EF7 & EF11. The tapes (for professional use) are selected in the individual manner, for each track as well. Analog tape recorders Ampex, Studer, Revox are used.

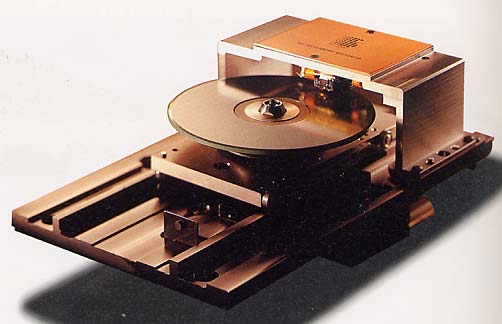

The resulting signal arrives at the CD-R professional recording system. It is built based on professional equipment PIONEER RPD 500pro and RPD 1000pro.

After numerous tests being conducted, two producers of CD-R, Verbatim Corporation (Mitsubishi Chemical Company) Extra Protection and Mobile Fidelity Sound lab., Inc., USA, Ultradisc 24 Karat Gold were selected for application.

Recording speed is REDUCED 4 times.

Thus, the obtained records are monitored using headphones STAX.

Sound, namely its growth compared with the original media, causes at least bewilderment: why does the original sound so bad!

![]()

Aleksey Oksanenko

StereoVideo&Multimedia /№12/Dec./2012